6 Trunnion Ball Valve ASTM A182 F316L 600 LB RTJ API 6D FULL BORE

VERVO trunnion ball valves are offered in 2 PC side entry, 3 PC side entry, welded body and top entry design in a wide range of carbon, stainless steel, duplex stainless steel, alloy and other special materials. VERVO trunnion ball valves are manufactured according to API 6D Design and fire safe tested per API 6FA and API 607 Standard.

EMERGENCY SEALS

For trunnion mounted ball valve size NPS 6 (DN 150) and above, it comes with provisions for sealant injection on both the stem and seat while for sizes NPS 5 (DN125) and below on body cavity. In case of failed underperformed seals, a temporary emergency seal can be achieved by injecting sealants.

ANTI-STATIC

Because the ball and stem in a ball valve are suspended on non-metallic parts, i.e. the seat seal and stem seal, there is a possibility a static charge may build up on the stem-ball, a mechanical (antistatic metal spring and ball) is introduced in the design to maintain the metal- to-metal contact between the rotating ball/stem and the valve body which will ground any charges to the valve body.

BLOWOUT PROOF STEM

The valve stem is made with a shoulder at the bottom end. It’s securely retained by the stuffing box, to avoid that the stem, under certain operating conditions, accidentally blows out. Other designs are available on request.

Body material: Available Forged (A105, A182 F304, F304L, F316, F316L, F51, F53, A350 LF2, LF3, LF5,) Casting (A216 WCB, A351 CF3, CF8, CF3M, CF8M, A995 4A, 5A, A352 LCB, LCC, LC2) Monel, Inconel, Hastelloy

Normal diameter:

Sizes:NPS 2 to NPS 48

Class:150 to Class 2500

End connection: BW, Flanged.

Pressure range: 150 lbs~250 lbs (PN16~PN420).

Operation: Lever, Gearbox, Electric, Pneumatic, Electro Hydraulic Actutor, Gas Over Oil Actuator.

Working temperature: -46℃~+200℃.

DESIGN FEATURES

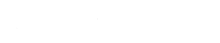

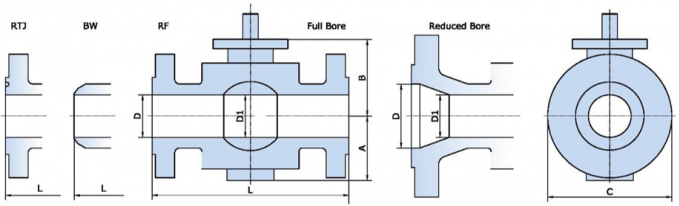

Full or Reduced Bore

RF, RTJ, BW or PE

Side entry, top entry, or welded body design

Double Block & Bleed (DBB),Double Isolation & Bleed (DIB)

Emergency seat and stem injection

Anti-Static Device

DESIGN STANDARD

Design & manufacture according to API 6D, API 608, ISO 17292

Face-to-face according to API 6D, ASME B16.10

End Connection according to ASME B16.5, ASME B16.47, MSS SP-44 (NPS 22 Only)

Test & inspection according to API 6D, API 598

Fire safe design according to API 6FA, API 607

Also available per NACE MR-0175, NACE MR-0103, ISO 15848

ASME CLASS 600 (PN 100) FULL BORE

|

Size

in/mm

|

D

|

D1

|

L |

Casting |

Forging |

Weight |

| RF |

RTJ |

BW |

A |

B |

C |

A |

B |

C |

RF/RTJ

(lb/kg)

|

BW

(lb/kg)

|

|

2

50

|

1.93

49

|

1.93

49

|

11.5

292

|

11.63

295

|

11.5

292

|

3.7

95

|

5.7

145

|

6.5

165

|

3.3

83

|

5

126

|

6.5

165

|

62

28

|

57

26

|

|

2 ½

65

|

2.44

62

|

2.44

62

|

13

330

|

13.13

333

|

13

330

|

3.9

100

|

6.3

160

|

7.7

195

|

3.7

95

|

5.9

150

|

7.4

188

|

119

54

|

106

48

|

|

3

80

|

2.94

74

|

2.94

74

|

14

356

|

14.13

359

|

14

356

|

5

128

|

7.2

184

|

8.3

210

|

4.6

117

|

6.1

155

|

8.3

210

|

165

75

|

159

72

|

|

4

100

|

3.94

100

|

3.94

100

|

17

432

|

17.13

435

|

17

432

|

5.8

148

|

8.2

209

|

11.6

295

|

5.4

138

|

7

177

|

10.8

275

|

242

110

|

209

95

|

|

5

125

|

5

127

|

5

125

|

20

508

|

2012

511

|

20

508

|

6.7

170

|

8.2

208

|

13.4

340

|

6.5

165

|

8

202

|

13

330

|

407

185

|

352

160

|

|

6

150

|

5.94

150

|

5.94

150

|

22

559

|

22.13

562

|

22

559

|

7.7

195

|

9.8

250

|

14

355

|

7

178

|

9

228

|

14

355

|

551

250

|

511

232

|

|

8

200

|

7.91

201

|

7.91

201

|

26

660

|

26.13

663

|

26

660

|

9.6

245

|

11.1

283

|

16.5

420

|

9.6

245

|

10.5

267

|

16.5

420

|

914

415

|

727

330

|

|

10

250

|

9.92

252

|

9.92

252

|

31

787

|

31.13

790

|

31

787

|

11.4

290

|

12.6

320

|

20

510

|

11.9

302

|

12.3

312

|

20

510

|

1652

750

|

1564

710

|

|

12

300

|

11.94

303

|

11.94

303

|

33

838

|

33.13

841

|

33

635

|

14.2

360

|

15.3

390

|

22.8

580

|

13.8

350

|

14.5

368

|

22.6

573

|

2024

919

|

1808

820

|

|

14

350

|

13.19

334

|

13.19

334

|

35

889

|

35.12

891

|

35

889

|

15.6

395

|

16.1

410

|

25

635

|

15

380

|

15.6

396

|

24.8

630

|

2863

1300

|

2445

1110

|

|

16

400

|

15.19

385

|

15.19

385

|

39

991

|

39.13

994

|

39

991

|

16.7

425

|

17.2

436

|

28.3

720

|

17.3

440

|

17.5

444

|

16.7

423

|

3722

1690

|

33304

1500

|

|

18

450

|

17.19

436

|

17.19

435

|

43

1092

|

43.13

1095

|

430

1092

|

19.3

490

|

20.3

515

|

32.3

820

|

18.9

480

|

20

510

|

31.9

810

|

5176

2350

|

4670

2120

|

|

20

500

|

19.17

487

|

19.17

487

|

47

1194

|

47.25

1200

|

47

1194

|

22.6

575

|

22.7

576

|

36.2

920

|

20.6

522

|

20.7

525

|

34.4

875

|

6500

2950

|

6013

2730

|

|

22

550

|

21.19

538

|

21.19

538

|

51

1295

|

51.38

1305

|

51

1295

|

20.5

520

|

22

560

|

37.8

960

|

20.3

515

|

26.7

550

|

37.4

950

|

6938

3150

|

6432

2920

|

|

24

600

|

23.19

589

|

23.19

589

|

55

1397

|

55.38

1407

|

55

1397

|

23.8

605

|

25.2

640

|

41

1043

|

24.4

619

|

25.2

641

|

41.3

1050

|

10573

4800

|

9692

4400

|

|

26

650

|

24.94

633

|

24.94

633

|

57

1448

|

57.5

1461

|

57

1448

|

25.6

650

|

26.4

670

|

43.9

1115

|

25.5

640

|

26.2

665

|

43.3

1100

|

11718

5320

|

10683

4850

|

|

28

700

|

26.94

684

|

26.94

684

|

61

1549

|

61.5

1562

|

61

1594

|

26.8

680

|

23.3

720

|

48

1220

|

26.6

675

|

28.1

715

|

47.6

1210

|

17400

7900

|

16410

7450

|

|

30

750

|

28.94

735

|

28.94

735

|

65

1651

|

65.5

1664

|

65

1651

|

29.9

760

|

30.6

777

|

51.8

1315

|

29.1

740

|

30.6

776

|

51

1295

|

19600

8900

|

18612

8450

|

|

32

800

|

30.69

779

|

30.69

779

|

70

1778

|

70

1778

|

70.63

1794

|

31.1

790

|

31.5

790

|

55.5

1410

|

30.9

785

|

31.3

794

|

53.9

1370

|

20240

9200

|

18260

8300

|

|

34

850

|

32.69

830

|

32.69

830

|

76

1930

|

76.61

1946

|

76

1930

|

33.1

840

|

33.9

860

|

56.3

1480

|

32.7

830

|

33.5

850

|

57.5

1460

|

29295

13300

|

25300

11500

|

|

36

900

|

34.41

874

|

34.41

874

|

82

2083

|

82.63

2099

|

82

2083

|

35

890

|

36.6

930

|

60.9

1546

|

35.4

900

|

36.2

920

|

60.9

1548

|

30176

13700

|

27533

12500

|

|

40

1000

|

38.44

976

|

38.44

976

|

80.71

2050

|

(1) |

80.71

2050

|

37.8

960

|

38

965

|

65.6

1665

|

37.4

950

|

37.6

955

|

65.2

1655

|

31460

14300

|

29172

13260

|

|

42

1050

|

40.19

1020

|

40.19

1020

|

82.68

2100

|

(1) |

82.68

2100

|

40.9

1040

|

41.7

1060

|

72.8

1850

|

40.6

1030

|

41.3

1050

|

71.7

1820

|

36080

16400

|

33660

15300

|

|

48

1200

|

45.94

1166

|

45.94

1166

|

94.49

2400

|

(1) |

94.49

2400

|

46.9

1190

|

46.3

1175

|

78.3

1990

|

46.5

1180

|

45.9

1165

|

77.6

1970

|

49940

22700

|

46200

21000

|

|

56

1400

|

53.56

1360

|

53.56

1360

|

106.3

2700

|

(1) |

106.3

2700

|

54.5

1385

|

54.3

1380

|

93.5

2375

|

54.2

1376

|

53.5

1360

|

92.6

2352

|

81400

37000

|

30800

14000

|

ASME CLASS 600 (PN 100) REDUCE BORE

|

Size

in/mm

|

D

|

D1

|

L |

Casting |

Forging |

Weight |

| RF |

RTJ |

BW |

A |

B |

C |

A |

B |

C |

RF/RTJ

(lb/kg)

|

BW

(lb/kg)

|

|

2x1 ½

50x40

|

1.93

49

|

1.5

38

|

11.5

292

|

11.62

295

|

11.5

292

|

3.7

94

|

5.28

134

|

6.5

165

|

3.3

83

|

4.5

115

|

6.5

165

|

53

24

|

46

21

|

|

2 ½x2

65x50

|

2.44

62

|

1.93

49

|

13

330

|

13.13

333

|

13

330

|

3.7

95

|

5.7

145

|

7.5

190

|

3.3

83

|

5

126

|

7.5

190

|

95

43

|

64

29

|

|

3x2

80x50

|

2.94

74

|

1.93

49

|

14

356

|

14.13

359

|

14

356

|

3.7

95

|

5.7

145

|

8.3

210

|

3.3

83

|

5

126

|

8.3

210

|

93

42

|

86

39

|

|

4x3

100x80

|

3.94

100

|

2.94

74

|

17

432

|

17.13

435

|

17

432

|

5.4

138

|

7.2

184

|

10.8

275

|

5.5

138

|

6.1

155

|

10.8

275

|

187

85

|

150

68

|

|

6x4

150x100

|

5.94

150

|

3.94

100

|

22

559

|

22.13

562

|

22

559

|

7

178

|

8.2

208

|

14

355

|

7

178

|

7

177

|

14

355

|

330

150

|

187

85

|

|

8x6

200x150

|

7.94

201

|

5.94

150

|

26

660

|

26.13

663

|

26

660

|

8.3

210

|

9.8

250

|

16.5

420

|

8.3

210

|

9

228

|

16.5

420

|

638

290

|

528

240

|

|

10x8

250x200

|

9.94

252

|

7.94

201

|

31

787

|

31.13

790

|

31

787

|

9.6

245

|

11.1

283

|

20

510

|

9.6

245

|

10.5

267

|

20

510

|

1256

570

|

1167

530

|

|

12x10

300x250

|

11.94

303

|

9.94

252

|

33

838

|

33.13

841

|

33

838

|

11.4

290

|

12.6

320

|

22

560

|

11.9

302

|

12.3

312

|

22

560

|

1762

800

|

1608

730

|

|

14x10

350x250

|

13.19

334

|

9.94

252

|

35

889

|

35.13

892

|

35

889

|

11.4

290

|

12.6

320

|

23.8

605

|

11.9

302

|

12.3

312

|

23.8

605

|

2489

1130

|

2247

1020

|

|

16x12

400x300

|

15.19

385

|

11.94

303

|

39

991

|

39.13

994

|

39

991

|

14.1

360

|

15.4

390

|

27

685

|

13.8

350

|

14.5

368

|

27

685

|

3414

1550

|

2930

1330

|

|

18x14

450x350

|

17.19

436

|

13.19

334

|

43

1092

|

43.13

1095

|

43

1092

|

15.6

395

|

16.1

410

|

29.3

745

|

15.2

385

|

15.6

396

|

29.3

745

|

4405

2000

|

3965

1800

|

|

20x16

500x400

|

19.19

487

|

15.19

385

|

47

1194

|

47.25

1200

|

47

1194

|

16.7

425

|

17.2

436

|

32

815

|

17.3

440

|

17.5

444

|

32.1

815

|

5727

2600

|

5286

2400

|

|

24x20

600x500

|

23.19

589

|

19.19

487

|

55

1397

|

55.38

1407

|

55

1397

|

22.6

575

|

22.7

576

|

37

940

|

20.6

522

|

20.7

525

|

37

940

|

6500

3950

|

7819

3550

|

|

30x24

750x600

|

28.94

735

|

23.19

589

|

61

1651

|

65.5

1664

|

65

1651

|

23.8

605

|

25.2

640

|

42.9

1090

|

24.4

619

|

25.2

641

|

42.9

1090

|

18722

8500

|

17621

8000

|

|

36x30

900x750

|

34.41

874

|

28.94

735

|

82

2083

|

82.63

2099

|

82

2083

|

35

890

|

36.6

930

|

60.9

1546

|

35.4

900

|

36.2

920

|

60.9

1548

|

23965

10880

|

20925

9500

|

(1) Contact our sales representative for more information.

Keywords of 6 Trunnion Ball Valve ASTM A182 F316L 600 LB RTJ API 6D FULL BORE

DN600 Ball Valve,Forging Steel Stainless Steel A182 F316L Ball Valve,3Piece Ball Valve,Soft Seal Ball Valve,Carbon Steel A182 F316L ,3 Piece Ball Valve,Forging steel Stainless Steel Ball Valve,API 6D Ball Valve,Trunnion Mounted Ball Valve,6Inch Forging Steel Stainless Steel Ball Valve

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!